Shieldon Knives: How They Are Made

Shieldon was established in 1998 as a manufacturer of knives of all kinds. For the years that the company has been operational, it has continued to deliver high-quality products for a wide-ranging demographic. The technology and the expertise that goes into the production of the knives are among the best in the industry and one of the reasons why it continues to grow bigger every year. But how are these knives made? Is there a special process to it, or are the raw materials simply unique?

These are the questions we are going to address here. We will be looking at the manufacturing process that Shieldon uses to make their knives and the raw materials used. If knives are your forte, then this is exactly what you need to be introduced to high-grade knives.

Top Raw Materials

A knife is only as good as the raw materials used in its manufacturing. The better the quality of the raw materials, the stronger the resulting knife. These are factors that Shieldon puts into consideration when selecting the materials and the most common ones in use include the following.

Tool Steel

Tool steel is a special type of metal that is made by blending carbon and alloy steels which usually add hardness, wear resistance, and toughness to the knives. Like most of the other steel types, tool steel is also cheap to access and make, and these are some of the reasons why many knife manufacturers prefer them over others. Other elements that are present in this type of raw material include chromium, tungsten, vanadium, and molybdenum, but in small quantities, all adding their respective attributes to the overall quality.

Carbon Steel

Carbon steel is a lot more complicated than all the other types and the most expensive too. This is steel that has a higher concentration of carbon, and this introduces new properties to the entire structure. Carbon steel is a rather new phenomenon that is now being used widely, and the reasons for that are many. Carbon is a stronger element, and blades that are made using carbon steel are among the strongest, with high levels of toughness and wear resistance. There’s also the advantage of aesthetics; a knife made using carbon steel looks great.

Stainless Steel

This is the most common and the cheapest form of steel. It is also one of the oldest materials used for knives, and a lot of other variations are derived from it. Stainless steel used to have issues regarding edge retention and wear resistance, but technological advancements have now made it to be at par with higher steels like Carbon steel. Knives made using stainless steel have been found to be long-lasting, easy to maintain, cheap, and widely available.

The Process

Like any other manufacturing process, making follows well-defined stages, with each phase handling a particular property of the knife. Shieldon is particular about the quality, and for this reason, each stage is very intense. The following are the stages through which the knives are made.

Steel Plate Stamping

This is the first stage, and it involves the selection of the steel bar from a pile. Once the right bar is found, it is placed into a high-powered stamping machine, and the blade form is forcefully stamped on the sides or one side, depending on the knife type being made. This process is handled by well-trained experts who have the experience needed to pull this off as it is an artistic role. This is the point where the eventual shape and design of the knife are determined.

Hole Punching

The second phase is called Hole Punching, and it is handled by a 16T punch drill press. The holes are punched into the stamped thick steel on the ends where the knife handle will be attached to. The range of these holes usually ranges from 4mm to 6mm in diameter, just big enough to house the rivets and bolts that will be needed later on. The 16T punch drill press is a reliable and hardy tool, ensures and this process is very fast.

Straightening & Heat Treating

The third phase involves straightening and heat treatment that ensure the blade is straight and tough. The knife is put through a straightening machine that irons out any deformity. This is the part where the knife surface becomes smooth and even. The next step is heat treatment, and the knife is subjected to high temperatures in a kiln or an oven for a set period of time. Then they are cooled down in a slow process giving the blades the ability to retain their form even when they are bent. Success in this stage is what determines how durable a knife would eventually be.

Detail-Oriented Processing

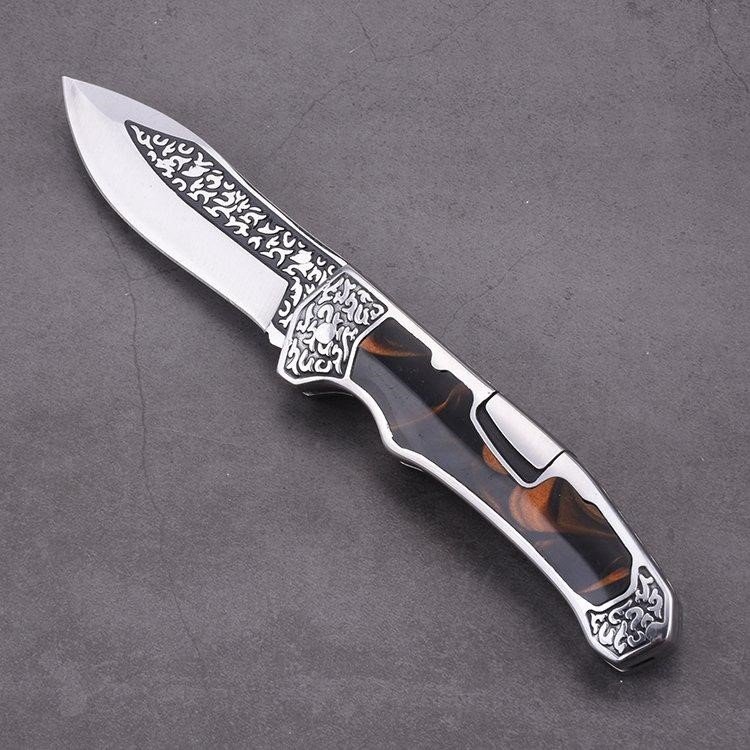

At this stage, the blade is given an artistic treatment. A group of highly skilled artisans gets down to work to carve out all kinds of patterns defending the order instructions. This is done through the use of sophisticated engraving machines. For someone to qualify to be on this team, they must possess vast experience and must have an eye for art since Shieldon is very particular about how the final product looks like. This stage has three main processes that include the following.

- Grinding: Once the art has been added, the next stage is called the Grinding phase. In this stage, all the rough edges that still exist are smoothed out and eliminated to give the knife that complete look. It is at this point that the knife begins looking exactly how it would in the end.

- Miling: This is the part where the edges are given a more detailed rework to give the cutting edge that signature shiny look. It is done using water and handed in the most delicate of ways to avoid overdoing it.

- Polishing: Once all the cleaning has been completed, the final touch is polishing. This is the stage where the blade is put through a rigorous polishing routine to give it a stunning and shiny glow that high-end blades are known for.

Surface Finishing

Surface finishing is the next step, and it involves a general polish to give the knife a final form. This is done through a number of specific treatment methods that include sanding, titanium plating, sandblasting, mirror polishing, non-stick spray painting, and thermal transfer. This is also the point where logos and other branding elements are added in strategic places depending on the job brief.

This stage is handled by people who are adept with their hands because any slight mistake may lead to damage, forcing the knife blade to be reforged and placed back into the process from the beginning. Shieldon knives have some of the best surface finishing around, and you only need to check the online catalog out to see this.

Blade Beveling

Blade beveling is another critical process that involves the creation of bevels by holding the knife against a grinding wheel. This is a delicate process that requires focus and precision because a single mistake may cause the knife to be uneven; for this reason, only the experts are allowed to handle this section of the manufacturing process to ensure there’s uniformity in the blade edges in all the knives that come off the assembly line. The process is repeated on both sides of the blade to ensure that the angles are symmetrical. This is how you can tell the quality of a knife; the effort can be seen on the blade beveling.

Cleaning and Packaging

The final stage of knife manufacturing is cleaning and packaging. Once the knife has undergone all the processes above, it is cleaned thoroughly to ensure that no other blemish still exists. This cleaning also gets rid of all the loose residue from the grinding process. Once the right level of cleanliness is attained, the knife is packaged nicely based on the client’s preferences and made ready for shipping.

Quality control is also part of the entire process. Several random knives are picked from the finished batch and put through rigorous tests to check their toughness, hardness, performance, and other important aspects. They have to attain certain scores for the knives to be certified ready for use.

The Shieldon Factory

The Shieldon factory is located in Guangdong and sits on 27,000 square meters of land, a space that is big enough to accommodate the massive manufacturing plant. The annual capacity is about 120,000 blade pieces in a year which are consumed around the globe with over 3,000 long-term clients. The factory is strategically located in an area that gives it access to raw materials and shipping routes to the rest of the country.

Conclusion

Knife manufacturing is not a complicated process, but it takes only the best to get things running, something that Shieldon (pocket knife manufacturer) has been doing for 23 years now. There are many other plates in the market with their own unique products, but if reliability is what you are looking for, then Shieldon knives should be top of your priority list. For more information on knives and where you can get them quickly, check out our website.

Article source:Shieldon Knives: How They Are Made | Shieldon